Classification of Warmth Exchangers

Warmth exchangers for water cooling are appropriate both in nuclear energy stations and in chillers of public structures (shopping centers, office premises, and so forth). Generally speaking, in refrigeration innovation, water is cooled by York replacement coils: freon passes from the fluid stage to the vaporous one, since the warmth taken from the water is moved to the coolant.

For the situation when a warmth exchanger for cooling water is utilized at a CHP plant, there is water in the two circuits. These gadgets are for the most part intended to give a lot of warmth expulsion. The chilly coolant in such gadgets is water from cooling pinnacles or shower pools (the alleged coolers), the working expense of which is very high because of the expense of siphoning fluid through them.

Plate Heat Exchangers

Condenser coil replacement for Trane chillers productively move heat, is conservative and advantageous. These devices don’t need uncommon support, they can work for quite a while at high temperatures and huge pressing factors. Applications: cooling, warming, vanishing, and buildup of working media. They are effectively utilized in food creation and drugs, heat trade, and climatic frameworks warming frameworks, and boiling water supply.

Shell and Cylinder Heat Exchangers

Cylinder lattices are welded to the packaging, packaging at the closures, in which the cylinder groups are fixed. Fundamentally, pipes in frameworks are secured with a flare seal or in another manner, contingent upon the line material and the pressing factor in the device.

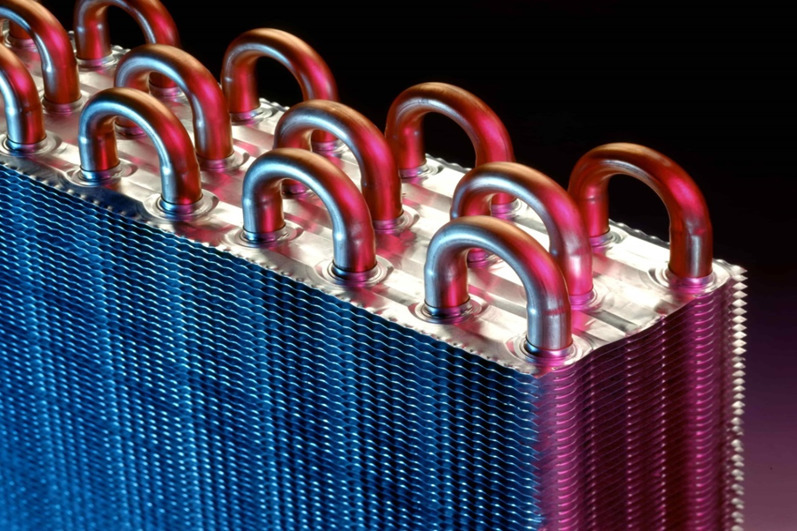

In a multi-pass heat exchanger, parts are introduced in the body and covers to speed up the warmth transporters. To expand the warmth move, the ribbing of the warmth trade tubes is utilized, which is performed either by knurling or by winding a tape. On the off chance that essential, the plan of the contraption ought to accommodate its cleaning.